Strategic R&D, Manufacturing Transfer, and Reverse Engineering: Reducing Medical Device Costs in Juárez

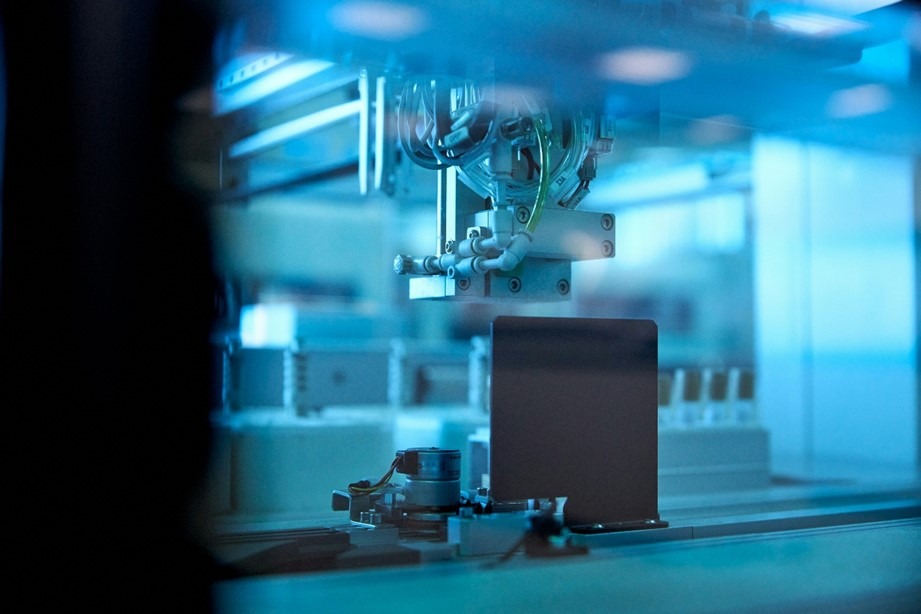

A successful manufacturing transfer requires more than just relocating complex machinery across a border; it demands strategic engineering and local expertise. Today, mostcompanies face rising costs and logistical nightmares due to distant markets. Rexmed Health simplifies this transition through specialized R&D and reverse engineering services. We transform complex production challenges into streamlined operations in Mexico. […]

The 2026 USMCA Medical Device Regulations Review: A Guide for MedTech OEMs

USMCA medical device regulations will face a critical assessment during the upcoming 2026 joint review of the North American trade agreement. Original Equipment Manufacturers (OEMs) must evaluate their current supply chains now.

Building MedTech Supply Chain Resilience with a Border-Based Partner

Building MedTech supply chain resilience through border-based partnerships or nearshoring focuses on reducing geographic distance and increasing logistical agility to mitigate global disruptions.

Sustainable Medical Device Manufacturing MedTech: Meeting ESG Goals via Nearshore Manufacturing

Sustainable medical device manufacturing represents the future of healthcare production for companies aiming to balance profit with environmental preservation. Modern MedTech leaders no longer view sustainability as a luxury or a side project; they recognize it as a core operational necessity. By shifting production closer to the end market, companies achieve remarkable efficiency. This article […]

How Medical Device DfM with a CMO Slashes Mass Production Costs

Medical device DfM transforms prototypes into profitable, scalable realities. Startups watch production costs spiral during scale-up transitions. Strategic CMO partnerships prevent this pitfall while accelerating timelines. Design for manufacturability eliminates waste before tooling investments to lock in costly mistakes. Experienced contract manufacturers reduce per-unit expenses by 30-50%. They turn concepts into market-ready products efficiently. Transitioning […]

Total Cost of Ownership vs. Unit Price: Medical Manufacturing TCO

Calculating medical manufacturing TCO (Total Cost of Ownership) instead of unit price is crucial because TCO encompasses all expenses over a product’s entire life cycle. On the contrary, the unit price only covers the initial acquisition cost or “sticker” price.

The Impact of AI in Medical Manufacturing and Real-Time Analytics on 2026

AI in medical manufacturing is changing this sector. By 2026, the union of smart algorithms and real-time evaluations have improved processes.

Labeling and Packaging Compliance: How to Pass Your Next FDA or ISO Audit

Passing an FDA or ISO audit is more than submitting paperwork. It requires a culture of precision, transparency, and full traceability. Every label, barcode, and package must connect seamlessly to manufacturing records. Compliance failures can delay approvals, harm a company’s reputation, and lead to costly recalls. For over three decades, manufacturers like Rexmed Health have […]

Smart Custom Medical Devices: From Design to Scalable Manufacturing

The demand for custom medical devices is increasing as medical attention shifts toward patient-centered care to achieve its objectives. Personalized and smart devices present themselves as cost-efficient and satisfying solutions for a technologically evolving field, such as medical equipment. This tendency necessitates a new approach to performing all tasks in the production chain, from design […]

Selecting the Right Binational Manufacturer: Key Criteria Beyond Compliance

Finding a binational manufacturer is a strategic decision in the medical device industry. And while regulatory compliance is essential, the most forward-thinking companies understand that the factors that truly define a strong partner extend beyond this. This article examines the five key criteria that companies must consider when selecting a partner. However, it’s not just […]